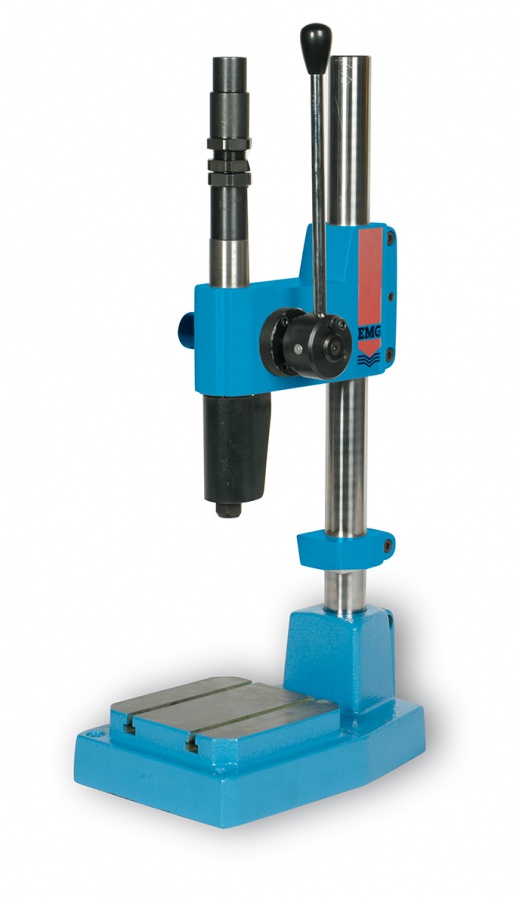

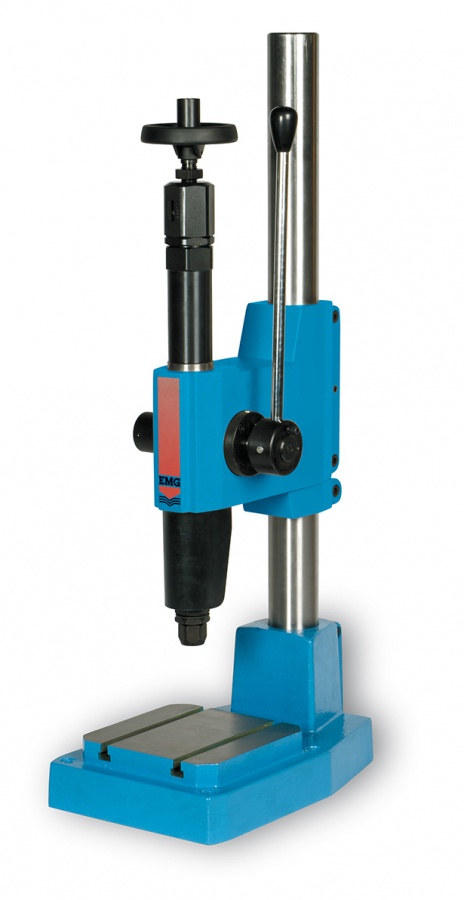

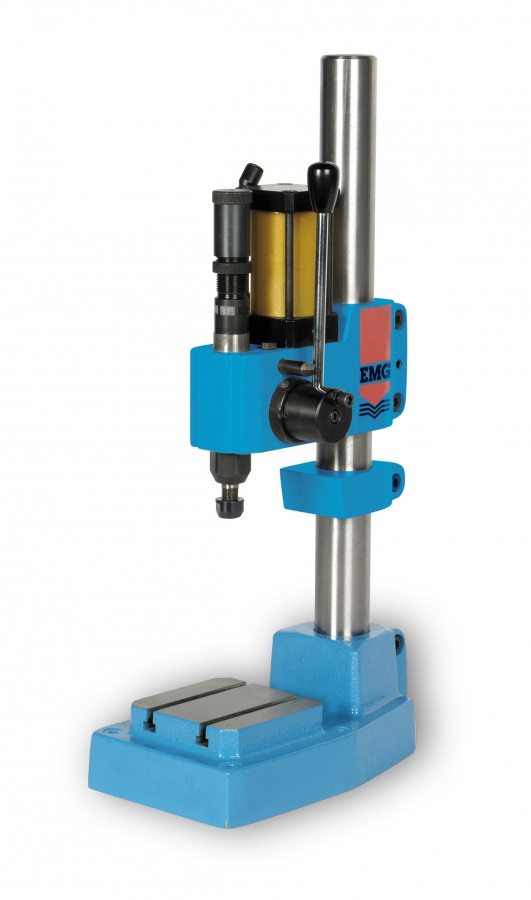

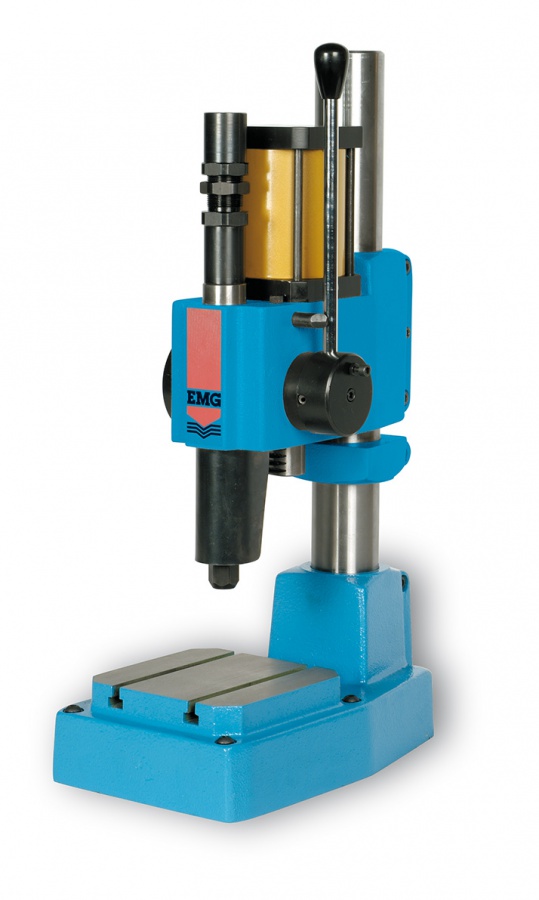

Impactor marking presses

Whatever the effort applied to the lever, the power of the marking presses is constant, regular and precise (power from 600 kg to 6000kg Stroke from 25 to 45 mm ). Their striking power is adjustable according to the material to be marked: metal, textile or plastic. EMG marking presses are equipped with an anti-double impact device to avoid any risk of unwanted second impact.

EMG impact marking presses are available in two main families: manual machines and pneumatic machines to meet the needs of moderate to high frequency marking.

Applications

At a time of ISO standardisation, part identification and traceability, EMG marking presses from 600 to 6000 kg offer a range of presses and accessories for marking, numbering, riveting and crimping that combine performance, precision and safety.

This range can be found in many workshops. The power delivered is constant and regular, and remains precise whatever the force applied to the lever. These presses feature adjustable striking power and a device that prevents double-striking.

These presses have an adjustable impact force and a mechanism which forbidding the double impact return effect.

MAIN FEATURES

- Counter, exhaust filter, anvil stakes, base support and lateral panels, marking accessories ...

CHARACTERISTICS:

- Precision and longevity with the adjusted slider locked for rotation

- Automatic raising of the slider by spring

- Quick and reliable adjustment of the clear height

- Mechanical stop ensuring repetiveness of the cycle

- Base support and press head made of FGL 250 cast iron

- No maintenance, no greasing

HOW TO CHOOSE A MARKING PRESS?

The EMG percussion marking presses are designed to make a cold impact on various materials. Marking allows the identification of a product and thus facilitates its traceability. Numbering or marking of different shapes and sizes can be achieved through the use of customized accessories and equipment.

The main characteristic to remember when choosing a marking press is its power. Indeed, this information will determine the maximum intensity that the machine tool can deliver in order to obtain a marking of maximum quality. Then, depending on the size of the parts to be marked, the free height and the depth of the gooseneck are important.

Finally, the length of the stroke is a determining element in order to adjust the striking power. Whether the press is manual or pneumatic, the operator determines the force to be applied in order to mark without risking the cutting of the machined part. The power delivered is constant and regular. It remains precise regardless of the force applied to the lever.

EMG's wide range of impact marking presses allows each professional to find the machine that meets his specific needs. Ranging from 600 to 6000 kg, the manual and pneumatic presses combine performance, precision and safety. Equipped with a device that prevents double impact, the impact is flawless.

EMG is a manufacturer of stamping presses as well as assembly presses, stamping/forming, deep drawing, cutting-out, bending or riveting.